The difference between the two forming die and the two color mold is:

A, two-color mold: two kinds of plastic materials in the same injection molding machine, two molding, but the product only mold once. Generally, this kind of molding process is also called double-material injection molding, usually completed by a set of molds, and requires a special two-color injection molding machine.

B. Rubber-coated mold (secondary molding): Two kinds of plastic materials are not necessarily injected into the same injection molding machine, forming twice; the product is removed from one set of molds, and then put into another set of molds for the second injection molding. Therefore, the general molding process is usually done by 2 sets of molds instead of a special two-color injection molding machine.

Summary of the two forming molds and two color moulds:

In the design of the secondary forming die, attention should be paid to the positioning of the hard adhesive, reliable sealing and ANTI-SLOPING holes should be made on the adhesive to prevent the deformation of the pulling adhesive.

Dual-color molds are becoming more and more popular in the market. This process can make the appearance of the products more beautiful, easy to change colors without spraying, but the cost is expensive and the technical requirements are high.

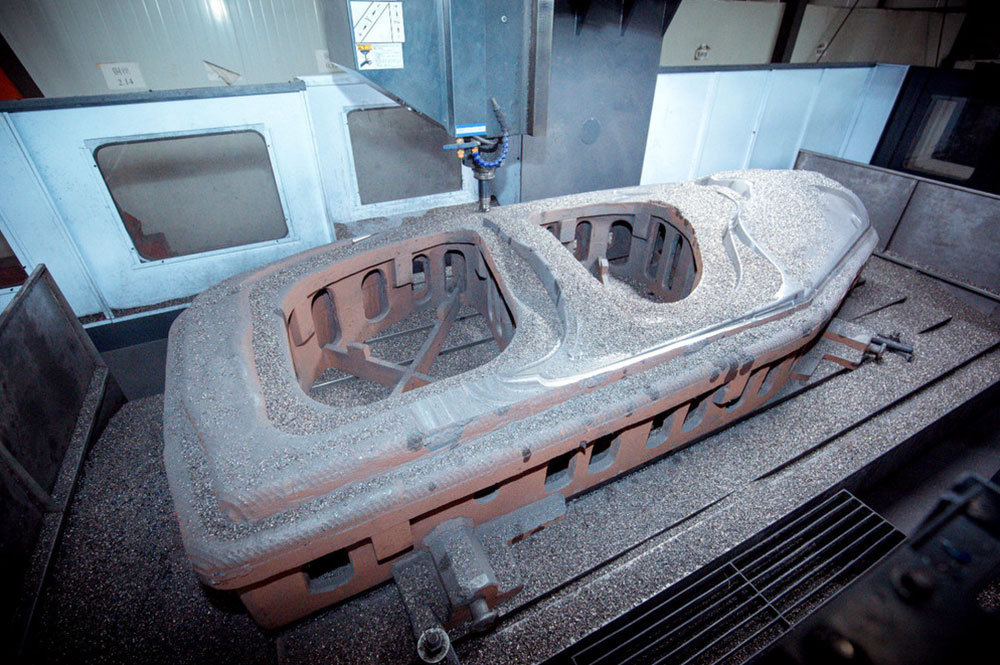

The two shapes of Cavity are different, forming 1 kinds of products respectively. The two shapes of Core are exactly the same.

The front and rear die of the die must be 180o after the center rotates. This check action must be done in design.

Pay attention to the position of the pinhole, the minimum distance is 210mm. Large mold should be appropriately increased the number of top hole. Moreover, because the ejector needle attached to the injection molding machine is not long enough, so we must design a lengthened ejector in the mold, the ejector needle grows out of the mold bottom plate about 150 mm. 2 locating rings must be designed on the back mold bottom plate.

The total thickness of the front panel plus the A board should not be less than 170mm. Please look carefully at other reference data for this type of injection molding machine, such as maximum die thickness, minimum die thickness, plug hole distance, etc.

The outlet of the three plate die is preferably designed to be automatic ejection. Special attention should be paid to whether the ejection action of the soft rubber nozzle is reliable.

The depth of the front SPRUE should not exceed 65mm. The distance from the top of the upper side (SPRUE) to the center of the mold is not less than 150mm.

In the design of CAVITY for the second injection, to avoid CAVITY insertion (or abrasion) damage to the glue level of the first molded product, a part of the avoidance can be designed. But we must carefully consider the strength of each sealing position, that is, in the injection molding, whether there will be a large injection pressure, plastic deformation, resulting in the second injection may have a batch front?

In injection molding, the product size of the first injection molding can be slightly larger, so that it can be pressed more tightly with another CAVITY in the second molding, in order to achieve the role of sealant.

Note that during the second injection, does the flow of the plastic impulse the first molded product to deform its glue position? If this is possible, we must try to improve it.

Before A or B plate clamping, it is necessary to notice whether the front mold Slider or Lifter will first reset and crush the product. In this way, we must try to make the A and B boards die first, then the SLIDER or LIFET of the front die can be reset.

Two CAVITY and CORE's water distribution should be as good as possible and balanced.

The 99% is to first injection the hard rubber part of the product, and then injection the soft rubber part of the product. Because soft rubber is easy to deform.

In order to make the two plastics "stick" tighter, the "stickiness" between the materials and the roughness of the mold surface should be considered. Bicolor injection has special TPU; and the more smooth the mold surface, the more sticky they are.

Pay attention to the positioning of the front and rear die, and all the insertion and break of the slope should be as large as 0.1mm.